Related Documents

Apollo

Highlights

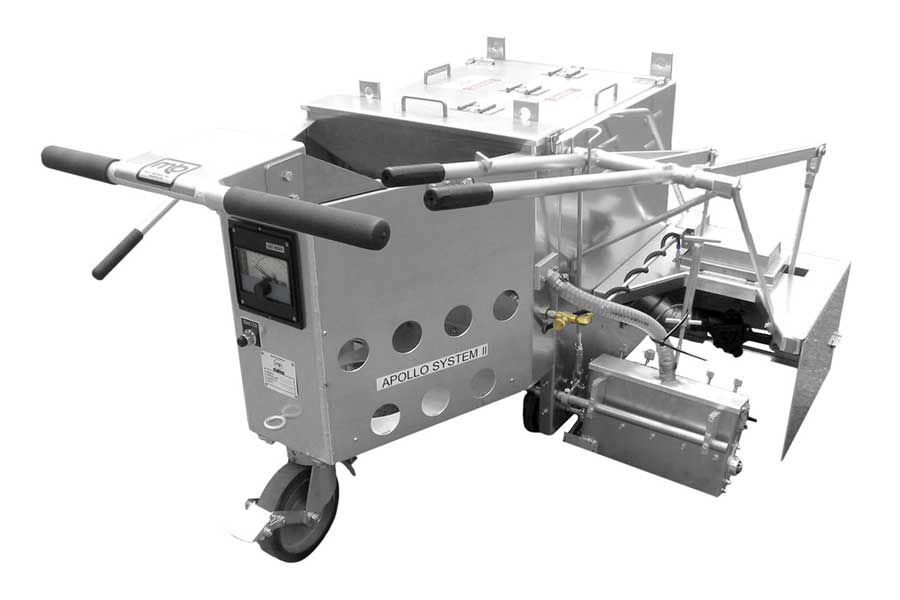

An extremely productive unit when used with separate melting kettles. This applicator can melt and apply over 700 square feet of markings in a normal work day, in stand-alone operations. Comes standard with double-ring high-efficiency burners, thermostat control system and metered glass beader. The Apollo III is the Basic Apollo II unit with the PlusOne Speedmelter installed.

-

One-Person Transport and Application

-

Simplest Method to Apply Hot-Melt Thermoplastic Markings

-

Heavy-Duty, Light Weight, Rust-Free Aluminum Construction

-

Thermostat-Controlled Burner

-

Accurate, High-Efficiency Melting

-

Rear Swivel Wheel

Equipment

-

Temperature Control:

Automatic temperature control

-

Application Rate:

Metered application for glass beads at 10 lbs per 100 sq ft

-

Application Die:

Precision die available in 4", 6", 8" and 12" and double 4" widths

-

Available Options:

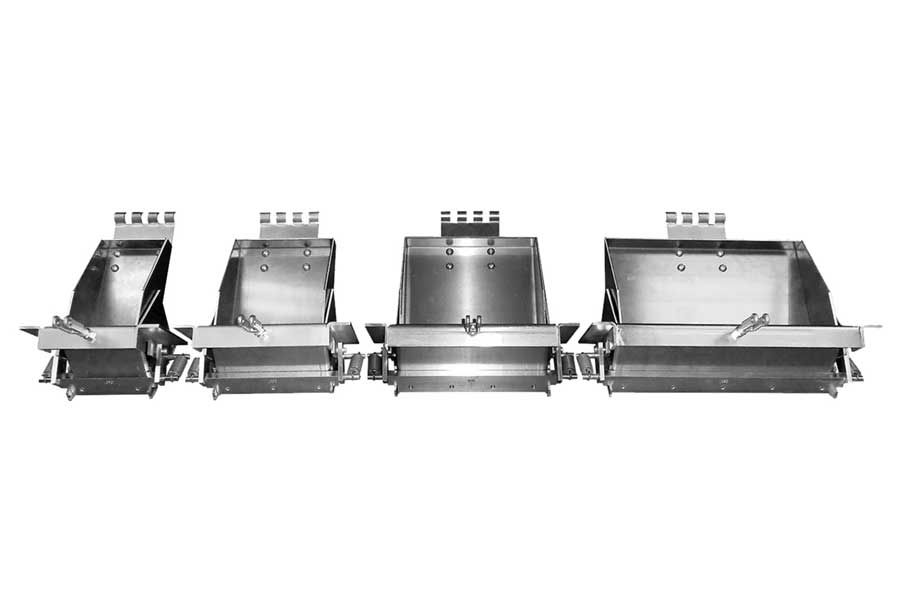

PlusOne Speedmelter System

Storage transport trailer

Double drop bead system